SELA provides unique solution with SELA’s Navigation SW Option which may perform navigation to specific defect on the small piece of wafer and unlike the SEM-FIB systems which may navigate on the whole wafer only as required by other navigation software packages. With SELA’s Navigation SW Option on MC600i you can easily recognize defect, navigate to defect and perform cross-section of the defect – all in one process.

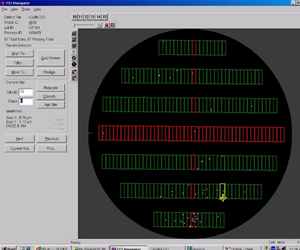

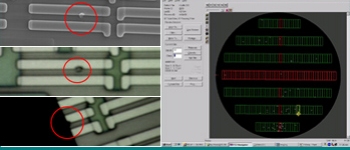

Navigation to defect in SEM-FIB system – recognition of the die with specific defect

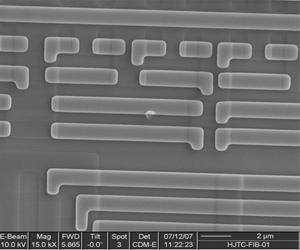

Navigation to defect in SEM-FIB system – recognition of the specific defect

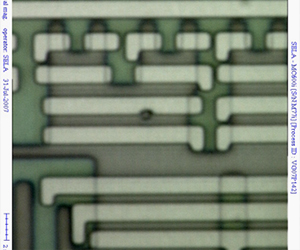

Navigation to defect in MC600i system – recognition of the specific defect

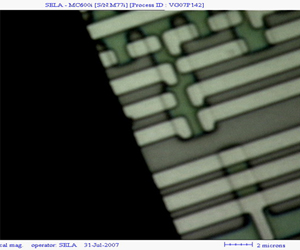

Cleaving of defect in MC600i system – result of successful accurate cleaving of the specific defect

Defect analysis is one of the most critical and time consuming task in understanding of failure and definition of corrective actions. Process of the recognition of the specific defect can be performed in multiple ways. One of the methods for recognition of specific defect is navigation to defect with software packages in SEM-FIB systems using Defect File from defect review stations.

SELA provides unique solution with SELA’s Navigation SW Option which may perform navigation to specific defect on the small piece of wafer and unlike the SEM-FIB systems which may navigate on the whole wafer only as required by other navigation software packages.

With SELA’s Navigation SW Option on MC600i you can easily recognize defect, navigate to defect and perform cross-section of the defect – all in one process.

MC600i performs cross-section of the defect by microcleaving and delivers two cleaved parts of defect for immediate analysis.

Sela’s proprietary MicroCleaving technology is unique in its ability to create precision cross-sections without water, chemical or mechanical contact, and to enable analysis of mirror images of a targeted feature.

Leave a Reply

Want to join the discussion?Feel free to contribute!