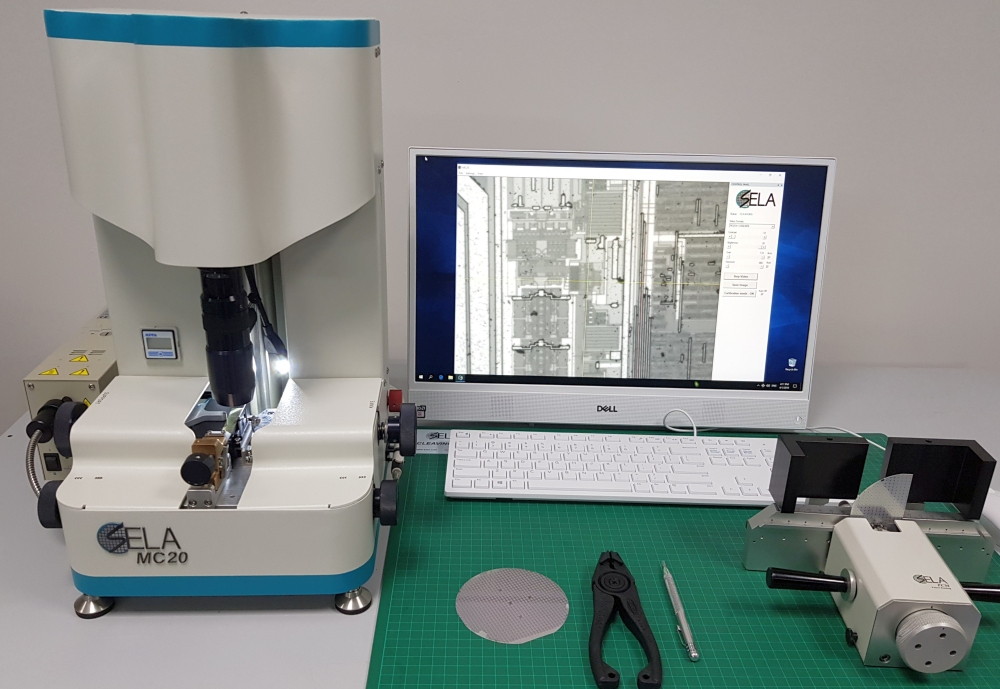

ENHANCED CAPABILITIES

- Semi-automatic controllable cleaving process for visible and buried defects

- Observation from top and bottom sides of the sample

- Registration and cross-section of buried defects

- Advanced white light and IR optics

FEATURES

- Accuracy better than 5 microns, mostly 2-3 microns

- Process time – single minute

- Small input sample or die – down to 4×2 mm

- Cleaving as close as 2 mm to the wafer or die edge

- Continuous cleaving of multiple targets

- Advanced optics with variable magnification up to 1000x

- Software controllable cleaving process

- Built-in vacuum

- “Maintenance free” servicing model

BENEFITS

- Turnaround time significantly reduced

- Improves yield analysis

- Improves characterization

- Improves and enhances SEM and FIN utilization

- Low cost of ownership

For additional information about SELA products please, contact us